DuBox, a modular design, and off-site construction company, will be showcasing the UAE’s first locally 3D printed concrete element from real life construction objects, at the key industrial summit to be held in Abu Dhabi. A leading designer of complete single or multi-storey concrete buildings using modular methodologies, DuBox said it will sponsoring a pilot project at the inaugural Global Manufacturing and Industrialisation Summit (GMIS) which will be held at the Paris-Sorbonne Abu Dhabi, UAE, from March 27 to 30. A joint initiative by the UAE Ministry of Economy and the United Nations Industrial Development Organisation (Unido), and co-hosted with the Abu Dhabi Department of Economic Development, the summit will be held under the patronage of Sheikh Mohamed bin Zayed Al Nahyan, Crown Prince of Abu Dhabi and Deputy Supreme Commander of the UAE Armed Forces. It is the world’s first global gathering for the manufacturing community, bringing together leaders in business, government and civil society to shape a vision for the sector’s future.

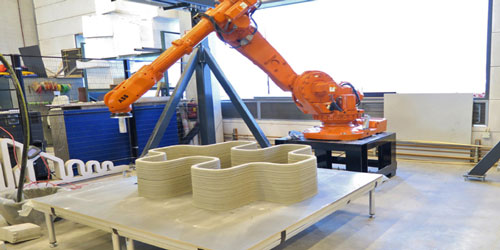

As a pioneer in the industrialisation of construction through modular, off-site construction solutions together with its global R&D (research and development) platform, DuBox will showcase its journey in innovation, bringing the building process from the site into a factory environment while rapidly prototyping new ideas and technologies. At GMIS, DuBox will also unveil as part of its R&D programme the UAE’s first locally 3D printed concrete element from real life construction objects, an achievement made possible through its collabouration with the University of Eindhoven in the Netherlands and the engineering consultancy firm of Witteveen+Bos, said a senior official. Chebel Bsaibes, the founder, and chairman of DuBox, said: “Since 2009, DuBox has handed over 150,000 sq m of built-up environment introducing new technologies and techniques, and, disrupting the conventional process of the construction industry.” Entire buildings are manufactured off-site in the DuBox factory, including all services and finishes, he stated. ”Modules are trucked or shipped pre-finished to job sites, where they are installed,” he added. Bsaibes said the company’s aim was to provide simpler-safer construction with faster completion times and smarter designs, for better value. ”We are paving the path for the construction industry to embrace the new smart industrial age – the fourth Industrial Revolution – by rapidly prototyping, testing, and commercialising innovative solutions” he noted. ”We are challenging and changing the way we build. Our participation at GMIS is a perfect opportunity to present what we have achieved over the last five years and what we have planned for the next five years,” he added.